A nice write up of the new ActiveSeam stitch and Merrow by Beth Purdue.

A link to the article:

http://www.southcoasttoday.com/

By Beth Perdue

October 25, 2013 2:11 PM

One of the first textile-related discoveries Charlie Merrow made, after becoming CEO of Merrow Sewing Machine Co. in 2004, was that garment designers didn't believe stitching added value to their customer brands.

Brand logos and materials, yes, but not stitching.

"My customers don't care," a New York lingerie manufacturer told Merrow when he began pitching a new, more flexible, stitch.

But Merrow and his brother Owen Merrow, company COO, believed otherwise. Stitching, they thought, could become the "design story" and create a whole new way for designers to brand their garments.

You just need the right stitch.

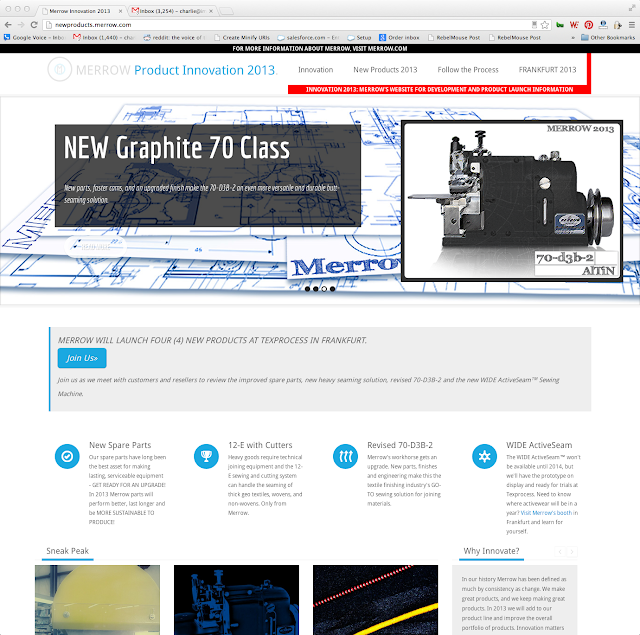

Fast forward nine years and the brothers have made good their idea, launching a new ActiveSeam 502 stitch and stitch design lab in October that they believe can contribute to a re-energized textile industry in Fall River.

At an Oct. 15 event to announce new innovations, Merrow said the ActiveSeam not only makes products that stretch better and are abrasion resistant, but can be used by designers to tell better product stories, essentially branding the stitch.

"When we created this we realized that we had something very different that was so good, so interesting, and so visible," he said. "Everybody wants an authentic story."

The ActiveSeam stitch was invented in 2010 and is made on Merrow sewing machines. The stitch has been publicly promoted for the past six months, according to Brian Foley, Merrow business development.

"We've been getting the message out that stitching matters," Foley said, adding that the company is also pushing the message that the stitch is more comfortable, offers complete linear stretch, and can be used to monetize a seam.

Flat on both sides, the stitch can be made in a variety of widths and designs to meet the needs of multiple fabrics and garments as well as the varying looks of company brands. It works for multiple clothing markets, from activewear and lingerie to medical garments or baby clothes.

What really got the attention of major manufacturers like Adidas, Nike, and Under Armor, Merrow said, was a triple-thread version that buries a third color beneath two outer threads and then reveals it when the garment stretches.

"Then we had something aesthetic," Merrow said. "It has been a transformative thing at Merrow."

A 175-year old company that got its start making gunpowder, Merrow Co., now Merrow Sewing Co., invented the overlock sewing machine and has been making them since 1838. The company has distributors in 65 countries with 300 agents selling products.

The Merrow brothers, great-grandnephews of company founder Joseph M. Merrow, moved the company to Fall River in 2008. Today, the company occupies a 30,000-square-foot open mill space on Bedford Street in the city.

With the ActiveSeam stitch, Merrow is also debuting a stitch design lab that can be used by other companies to design a unique version of the ActiveSeam stitch. Merrow can then outfit them with their sewing machines to make the stitch, Merrow said. Or, the company could, under a licensing program, develop the product in Fall River using local sewing companies like Griffin Manufacturing, a textile manufacturer located in the same mill space as Merrow.

The company expects to add three to five positions to its staff of 24 people with the launch of the stitch lab, Merrow said.

It is already beginning to use the stitch to make tactical vests for Maryland-based Velocity Systems.